GMG Unveils Graphene Aluminium-Ion Battery That Fully Charges in 6 Minutes

- Written by Reporters

Brisbane, Australia - Newsfile Corp. - December 15, 2025 - Graphene Manufacturing Group Ltd. (TSXV: GMG) (OTCQX: GMGMF) ("GMG" or the "Company") is pleased to provide the latest progress update on the Graphene Aluminium-Ion Battery technology ("G+AI") being developed by GMG and the University of Queensland ("UQ") under a Joint Development Agreement with Rio Tinto, one of the world's largest metals and mining groups, and with the support of the Battery Innovation Center of Indiana ("BIC") in the United States of America. Based on its current state of development as reflected below, the GMG G+AI Battery has similar performance characteristics to those provided by High Power Lithium Titanate Oxide ("LTO") batteries, which are sold at a premium price of up to US$1500/kWh. However, the GMG G+AI Battery can be produced at a substantially lower cost and therefore can be priced below that of LTO batteries. In 2025, sales of LTO batteries, which are used in many applications globally, totalled US$ 5.6[1] billion. Battery Performance Update: GMG is pleased to announce that it has progressed its G+AI Battery technology and believes that, once development is completed, it can meet the key target specification requirements for the main targeted battery use case as per Figure 1, including:  Figure 1: G+AI Battery Use Case - heavy mobile equipment To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_gmg_figure1.jpg GMG is pleased to share the energy densities of the current GMG G+AI pouch cell at 60 minutes and 6-minute charging compared to other chemistry batteries on the market (Figure 2), and a voltage vs capacity graph (Figure 3) of its latest G+AI Battery technology based on data provided by the third-party BIC battery testing laboratory. Based on that testing, the current stage of development, batteries produced by GMG and BIC had an energy density of 58 Wh/kg when charged in 1 hour and 26 Wh/kg when charged in 6 minutes. In 6-minute fast charging, the battery cells achieved 62% capacity in 3.2 minutes. The batteries had a nominal voltage of approximately 3.0 Volts and maintained performance over hundreds of cycles at 6-minute fast charging, without the significant degradation typically observed in lithium and sodium-ion batteries at such high charging rates.

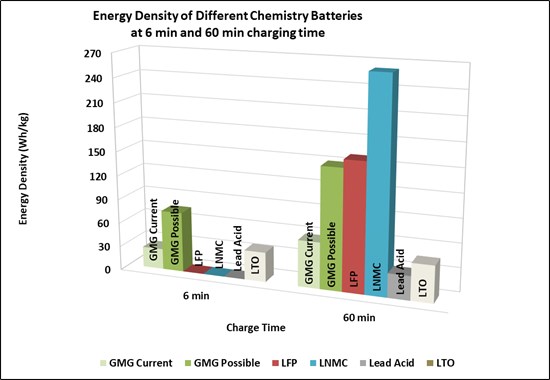

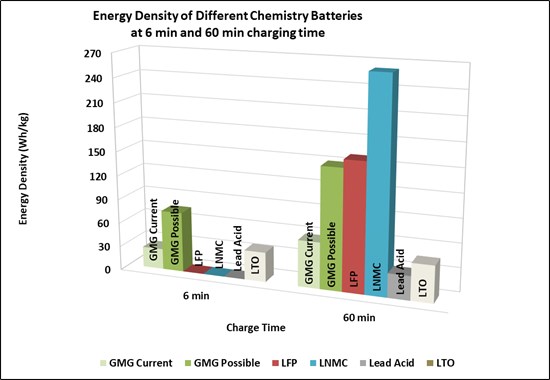

Figure 1: G+AI Battery Use Case - heavy mobile equipment To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_gmg_figure1.jpg GMG is pleased to share the energy densities of the current GMG G+AI pouch cell at 60 minutes and 6-minute charging compared to other chemistry batteries on the market (Figure 2), and a voltage vs capacity graph (Figure 3) of its latest G+AI Battery technology based on data provided by the third-party BIC battery testing laboratory. Based on that testing, the current stage of development, batteries produced by GMG and BIC had an energy density of 58 Wh/kg when charged in 1 hour and 26 Wh/kg when charged in 6 minutes. In 6-minute fast charging, the battery cells achieved 62% capacity in 3.2 minutes. The batteries had a nominal voltage of approximately 3.0 Volts and maintained performance over hundreds of cycles at 6-minute fast charging, without the significant degradation typically observed in lithium and sodium-ion batteries at such high charging rates.  Figure 2: Different Battery Chemistry Performance at 6 min and 60 min Charge[2] To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_002full.jpg Standard commercial Lithium Nickel Manganese Cobalt ("LNMC") and Lithium Iron Phosphate ("LFP") battery cells for electric vehicles and stationary storage are not designed for continuous 6-minute charging (10C); typical recommended charge rates are ≤1 hour (1C), often 2 hours (0.5C), with only limited fast charge operation. Only specialized high-power cell designs like LTO battery cells can tolerate charge rates of 6 minutes (10C).[3]

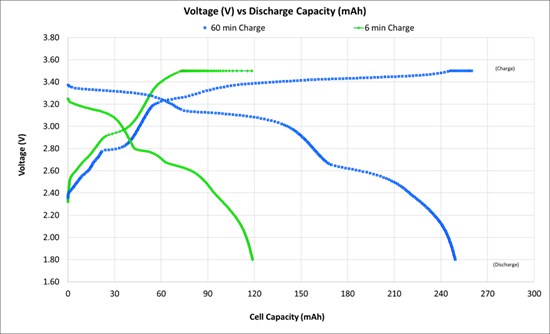

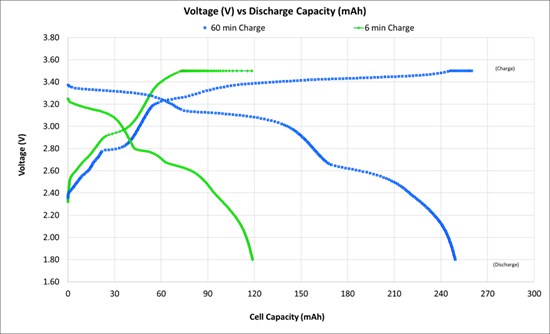

Figure 2: Different Battery Chemistry Performance at 6 min and 60 min Charge[2] To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_002full.jpg Standard commercial Lithium Nickel Manganese Cobalt ("LNMC") and Lithium Iron Phosphate ("LFP") battery cells for electric vehicles and stationary storage are not designed for continuous 6-minute charging (10C); typical recommended charge rates are ≤1 hour (1C), often 2 hours (0.5C), with only limited fast charge operation. Only specialized high-power cell designs like LTO battery cells can tolerate charge rates of 6 minutes (10C).[3] Figure 3: Battery performance curves of GMG's G+AI Battery at 60 min and 6min charge To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_003full.jpg GMG has now developed a completely new hybrid electrolyte that is chloride free and noncorrosive, unlike common aluminium battery electrolytes, along with a complex cathode and anode technology that enables very stable fast charging over several cycles. The substrate for both the cathode and anode in the GMG G+AI Battery is aluminium foil - which provides significant cost and weight savings compared with copper, the substrate material used in most lithium and sodium-ion batteries. GMG's technology does not include the use of lithium or copper. The Company has submitted an additional patent application covering these new developments. Craig Nicol, GMG Managing Director and CEO, commented: "I couldn't be happier with the GMG team to get to this point with our battery. We have rebuilt this battery in our weekly sprints from the ground up and developed completely new complex cathode, anode and electrolyte. This will provide a next generation fast charging battery technology currently not available in the world, and we look forward to sending out sample cells to test with partners in early 2026. This technology has many years of development in front of it and will improve as we keep pushing through known issues to improve capacity, voltage and reduce weight." GMG management believes that the Company's battery technology can eventually achieve over 150 Wh/kg when charged in 1 hour, and over 75 Wh/kg when charged in 6 minutes. The Company believes further development of the cathode, anode, electrolyte and component weights will eventually achieve this end goal. Figure 4 shows the latest Graphene Aluminium-Ion Battery multi-layer pouch cell.

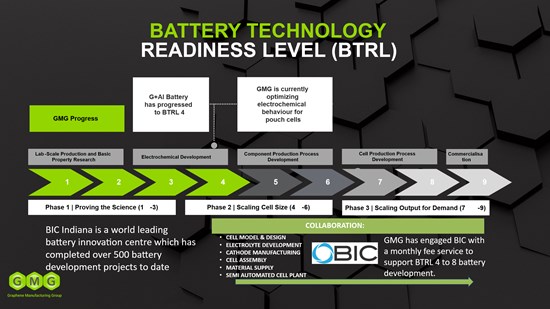

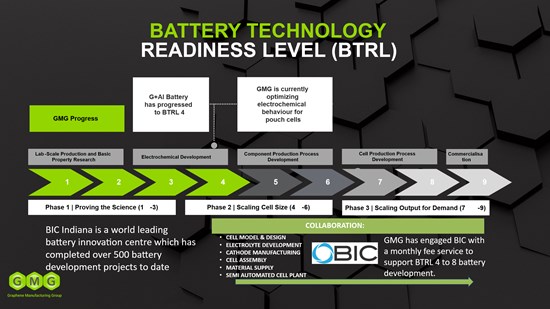

Figure 3: Battery performance curves of GMG's G+AI Battery at 60 min and 6min charge To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_003full.jpg GMG has now developed a completely new hybrid electrolyte that is chloride free and noncorrosive, unlike common aluminium battery electrolytes, along with a complex cathode and anode technology that enables very stable fast charging over several cycles. The substrate for both the cathode and anode in the GMG G+AI Battery is aluminium foil - which provides significant cost and weight savings compared with copper, the substrate material used in most lithium and sodium-ion batteries. GMG's technology does not include the use of lithium or copper. The Company has submitted an additional patent application covering these new developments. Craig Nicol, GMG Managing Director and CEO, commented: "I couldn't be happier with the GMG team to get to this point with our battery. We have rebuilt this battery in our weekly sprints from the ground up and developed completely new complex cathode, anode and electrolyte. This will provide a next generation fast charging battery technology currently not available in the world, and we look forward to sending out sample cells to test with partners in early 2026. This technology has many years of development in front of it and will improve as we keep pushing through known issues to improve capacity, voltage and reduce weight." GMG management believes that the Company's battery technology can eventually achieve over 150 Wh/kg when charged in 1 hour, and over 75 Wh/kg when charged in 6 minutes. The Company believes further development of the cathode, anode, electrolyte and component weights will eventually achieve this end goal. Figure 4 shows the latest Graphene Aluminium-Ion Battery multi-layer pouch cell.  Figure 4: Current Multi-Layer Battery Pouch Cell To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_004full.jpgBattery Technology Readiness Level The battery technology readiness level ("BTRL") of the G+AI technology remains at Level 4, see Figure 5. GMG is currently optimizing electrochemical behaviour for pouch cells via ongoing laboratory experimentation. Through collaboration with BIC, it is anticipated that the battery technology readiness will progress to BTRL 7 and 8 since the equipment and processes needed to produce the G+AI batteries are the same as those employed to make Lithium-Ion Batteries.

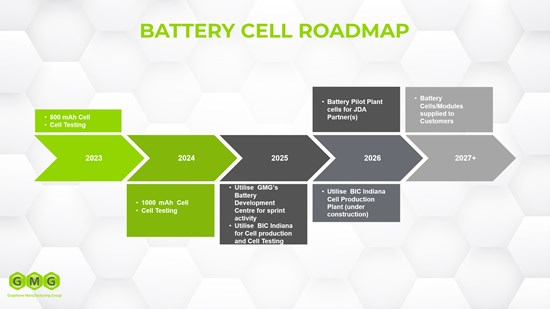

Figure 4: Current Multi-Layer Battery Pouch Cell To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_004full.jpgBattery Technology Readiness Level The battery technology readiness level ("BTRL") of the G+AI technology remains at Level 4, see Figure 5. GMG is currently optimizing electrochemical behaviour for pouch cells via ongoing laboratory experimentation. Through collaboration with BIC, it is anticipated that the battery technology readiness will progress to BTRL 7 and 8 since the equipment and processes needed to produce the G+AI batteries are the same as those employed to make Lithium-Ion Batteries.  Figure 5: Battery Technology Readiness Level (BTRL) To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_005full.jpg The Company is confident it can meet the overall timeline, as seen in Figure 6, of its battery cell roadmap that calls for testing of cells with customers in 2026 and small commercial production with support of various partners, including BIC, in 2027.

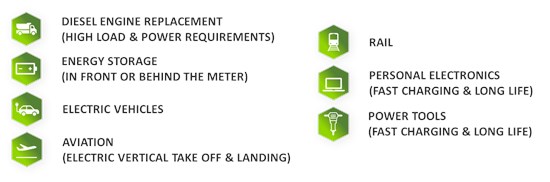

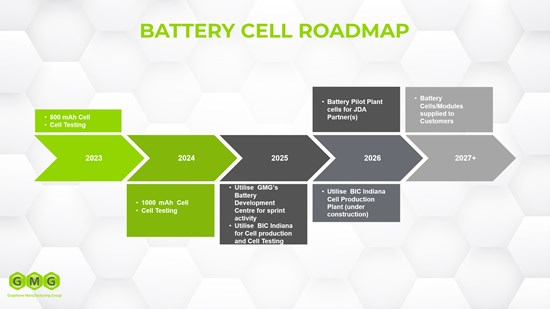

Figure 5: Battery Technology Readiness Level (BTRL) To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_005full.jpg The Company is confident it can meet the overall timeline, as seen in Figure 6, of its battery cell roadmap that calls for testing of cells with customers in 2026 and small commercial production with support of various partners, including BIC, in 2027.  Figure 6: Battery Cell Roadmap To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_006full.jpgNext Steps Toward Commercialisation & Market Applications Jack Perkowski, GMG Chairman and Non-Executive Director, commented: "I am extremely proud that GMG has progressed its battery to this stage. It is a significant milestone for the Company because the battery technology has so much opportunity in so many applications - especially in commercial vehicles. I look forward to the next updates as GMG makes further progress in the development of its battery technology." The Company continues to see a broad range of applications for a completed GMG G+AI Battery - utilising its ultra-high power-density and economic energy density characteristics. Along with Rio Tinto, a range of global companies have confidentially expressed their interest in working with GMG in the following vertical sectors:

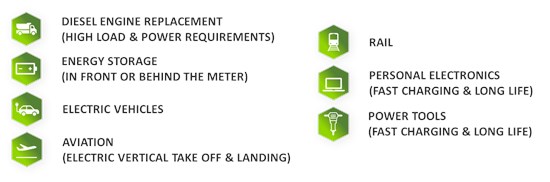

Figure 6: Battery Cell Roadmap To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_006full.jpgNext Steps Toward Commercialisation & Market Applications Jack Perkowski, GMG Chairman and Non-Executive Director, commented: "I am extremely proud that GMG has progressed its battery to this stage. It is a significant milestone for the Company because the battery technology has so much opportunity in so many applications - especially in commercial vehicles. I look forward to the next updates as GMG makes further progress in the development of its battery technology." The Company continues to see a broad range of applications for a completed GMG G+AI Battery - utilising its ultra-high power-density and economic energy density characteristics. Along with Rio Tinto, a range of global companies have confidentially expressed their interest in working with GMG in the following vertical sectors:  Figure 7: Market Applications To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_007full.jpg Currently, GMG believes it will use a plastic battery pack design, similar to Figure 8, to hold the battery pouch cells - reducing the weight, cost and complexity of using a metal case. Using a plastic battery pack is possible for two main reasons - GMG believes that its battery will not require a thermal management system or the fireproofing precautions provided by the metal case in a lithium-ion battery. Using plastic will increase the comparative energy density of GMG's G+AI battery packs when compared to lithium-ion batteries.

Figure 7: Market Applications To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_007full.jpg Currently, GMG believes it will use a plastic battery pack design, similar to Figure 8, to hold the battery pouch cells - reducing the weight, cost and complexity of using a metal case. Using a plastic battery pack is possible for two main reasons - GMG believes that its battery will not require a thermal management system or the fireproofing precautions provided by the metal case in a lithium-ion battery. Using plastic will increase the comparative energy density of GMG's G+AI battery packs when compared to lithium-ion batteries.  Figure 8: Expected Battery Pack for G+AIB Pouch Cells To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_008full.jpgComparison and Market Review: LTO Batteries As shown in Figure 9 below, the performance of GMG's G+AI battery technology is already very similar to LTO batteries. Figure 9: Comparison of Graphene Aluminium-Ion Battery (G+AI) to Lithium Titanate Oxide (LTO) Battery

Figure 8: Expected Battery Pack for G+AIB Pouch Cells To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_008full.jpgComparison and Market Review: LTO Batteries As shown in Figure 9 below, the performance of GMG's G+AI battery technology is already very similar to LTO batteries. Figure 9: Comparison of Graphene Aluminium-Ion Battery (G+AI) to Lithium Titanate Oxide (LTO) Battery

LTO batteries are sold at a premium to LFP and LNMC batteries, which are the main chemistries used in electric vehicles and energy storage systems, and are also widely used in other electronic applications due to their high performance and long cycle life. The material and manufacturing costs for GMG's G+AI Battery are expected to be similar to, or less than, the cost to manufacture standard lithium-ion batteries, but substantially lower than the costs to produce LTO batteries. LTO batteries have energy density ranging from 50 - 80 Wh/kg.[6] The LTO product is sold globally for use in many applications - with a total of US$5.6[7] billion sales per annum in 2025. Sales of LTO batteries are expected to grow at 10% per annum to an estimated US$ 9.0 billion by 2030. The major manufacturers of LTO batteries include Toshiba, Gree, Microvast and CATL. Further details on applications for the LTO battery from Mordor Intelligence7 are described below. In many of the use cases for LTO batteries, GMG believes that its G+AI Battery can be substituted at a substantially lower cost.

[1]Lithium Titanate Oxide Battery Market Size, Share & 2030 Growth Trends Report[2] LFP: https://www.evlithium.com/catl-battery-cell/catl-150ah-lifepo4-battery-cell.html LNMC: https://keheng-battery.com/product/catl-nmc-3-7v-151ah-high-energy-density-battery-for-ev/ LTO: https://www.global.toshiba/ww/products-solutions/battery/scib/product-next/product/cell/high-power.html Lead Acid: https://www.altronics.com.au/p/s4530-12v-3.5ah-sealed-lead-acid-sla-battery/?srsltid=AfmBOoqZGMEIsX__YYOuRLC3nvYDFtNkf35qZYuYeoh3ACf4wrrOLISD[3]https://findingspress.org/article/21459-impact-of-charging-rates-on-electric-vehicle-batt [4]High-power type cells | SCiB™ Rechargeable battery | Toshiba[5]https://www.ritarpower.com/industry_information/The-Price-of-50-kWh-Lithium-Ion-Batteries-A-Comprehensive-Analysis_297.html#:~:text=Lithium%20Titanate%20(LTO)%20Batteries%3A,cost%20between%20%2440%2C000%20and%20%2460%2C000. [6]https://www.grepow.com/blog/battery-energy-density.html[7]Lithium Titanate Oxide Battery Market Size, Share & 2030 Growth Trends Report

- Charging in under 6 minutes;

- Energy density > 100 Wh/kg after 1 hour of charging;

- Long Cycle Life (10,000 cycles);

- Safe (no Lithium);

- Lower Thermal Runaway Risk; and

- Likely no thermal management system will be needed.

Figure 2: Different Battery Chemistry Performance at 6 min and 60 min Charge[2] To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_002full.jpg Standard commercial Lithium Nickel Manganese Cobalt ("LNMC") and Lithium Iron Phosphate ("LFP") battery cells for electric vehicles and stationary storage are not designed for continuous 6-minute charging (10C); typical recommended charge rates are ≤1 hour (1C), often 2 hours (0.5C), with only limited fast charge operation. Only specialized high-power cell designs like LTO battery cells can tolerate charge rates of 6 minutes (10C).[3]

Figure 2: Different Battery Chemistry Performance at 6 min and 60 min Charge[2] To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_002full.jpg Standard commercial Lithium Nickel Manganese Cobalt ("LNMC") and Lithium Iron Phosphate ("LFP") battery cells for electric vehicles and stationary storage are not designed for continuous 6-minute charging (10C); typical recommended charge rates are ≤1 hour (1C), often 2 hours (0.5C), with only limited fast charge operation. Only specialized high-power cell designs like LTO battery cells can tolerate charge rates of 6 minutes (10C).[3] Figure 3: Battery performance curves of GMG's G+AI Battery at 60 min and 6min charge To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_003full.jpg GMG has now developed a completely new hybrid electrolyte that is chloride free and noncorrosive, unlike common aluminium battery electrolytes, along with a complex cathode and anode technology that enables very stable fast charging over several cycles. The substrate for both the cathode and anode in the GMG G+AI Battery is aluminium foil - which provides significant cost and weight savings compared with copper, the substrate material used in most lithium and sodium-ion batteries. GMG's technology does not include the use of lithium or copper. The Company has submitted an additional patent application covering these new developments. Craig Nicol, GMG Managing Director and CEO, commented: "I couldn't be happier with the GMG team to get to this point with our battery. We have rebuilt this battery in our weekly sprints from the ground up and developed completely new complex cathode, anode and electrolyte. This will provide a next generation fast charging battery technology currently not available in the world, and we look forward to sending out sample cells to test with partners in early 2026. This technology has many years of development in front of it and will improve as we keep pushing through known issues to improve capacity, voltage and reduce weight." GMG management believes that the Company's battery technology can eventually achieve over 150 Wh/kg when charged in 1 hour, and over 75 Wh/kg when charged in 6 minutes. The Company believes further development of the cathode, anode, electrolyte and component weights will eventually achieve this end goal. Figure 4 shows the latest Graphene Aluminium-Ion Battery multi-layer pouch cell.

Figure 3: Battery performance curves of GMG's G+AI Battery at 60 min and 6min charge To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_003full.jpg GMG has now developed a completely new hybrid electrolyte that is chloride free and noncorrosive, unlike common aluminium battery electrolytes, along with a complex cathode and anode technology that enables very stable fast charging over several cycles. The substrate for both the cathode and anode in the GMG G+AI Battery is aluminium foil - which provides significant cost and weight savings compared with copper, the substrate material used in most lithium and sodium-ion batteries. GMG's technology does not include the use of lithium or copper. The Company has submitted an additional patent application covering these new developments. Craig Nicol, GMG Managing Director and CEO, commented: "I couldn't be happier with the GMG team to get to this point with our battery. We have rebuilt this battery in our weekly sprints from the ground up and developed completely new complex cathode, anode and electrolyte. This will provide a next generation fast charging battery technology currently not available in the world, and we look forward to sending out sample cells to test with partners in early 2026. This technology has many years of development in front of it and will improve as we keep pushing through known issues to improve capacity, voltage and reduce weight." GMG management believes that the Company's battery technology can eventually achieve over 150 Wh/kg when charged in 1 hour, and over 75 Wh/kg when charged in 6 minutes. The Company believes further development of the cathode, anode, electrolyte and component weights will eventually achieve this end goal. Figure 4 shows the latest Graphene Aluminium-Ion Battery multi-layer pouch cell.  Figure 4: Current Multi-Layer Battery Pouch Cell To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_004full.jpgBattery Technology Readiness Level The battery technology readiness level ("BTRL") of the G+AI technology remains at Level 4, see Figure 5. GMG is currently optimizing electrochemical behaviour for pouch cells via ongoing laboratory experimentation. Through collaboration with BIC, it is anticipated that the battery technology readiness will progress to BTRL 7 and 8 since the equipment and processes needed to produce the G+AI batteries are the same as those employed to make Lithium-Ion Batteries.

Figure 4: Current Multi-Layer Battery Pouch Cell To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_004full.jpgBattery Technology Readiness Level The battery technology readiness level ("BTRL") of the G+AI technology remains at Level 4, see Figure 5. GMG is currently optimizing electrochemical behaviour for pouch cells via ongoing laboratory experimentation. Through collaboration with BIC, it is anticipated that the battery technology readiness will progress to BTRL 7 and 8 since the equipment and processes needed to produce the G+AI batteries are the same as those employed to make Lithium-Ion Batteries.  Figure 5: Battery Technology Readiness Level (BTRL) To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_005full.jpg The Company is confident it can meet the overall timeline, as seen in Figure 6, of its battery cell roadmap that calls for testing of cells with customers in 2026 and small commercial production with support of various partners, including BIC, in 2027.

Figure 5: Battery Technology Readiness Level (BTRL) To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_005full.jpg The Company is confident it can meet the overall timeline, as seen in Figure 6, of its battery cell roadmap that calls for testing of cells with customers in 2026 and small commercial production with support of various partners, including BIC, in 2027.  Figure 6: Battery Cell Roadmap To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_006full.jpgNext Steps Toward Commercialisation & Market Applications Jack Perkowski, GMG Chairman and Non-Executive Director, commented: "I am extremely proud that GMG has progressed its battery to this stage. It is a significant milestone for the Company because the battery technology has so much opportunity in so many applications - especially in commercial vehicles. I look forward to the next updates as GMG makes further progress in the development of its battery technology." The Company continues to see a broad range of applications for a completed GMG G+AI Battery - utilising its ultra-high power-density and economic energy density characteristics. Along with Rio Tinto, a range of global companies have confidentially expressed their interest in working with GMG in the following vertical sectors:

Figure 6: Battery Cell Roadmap To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_006full.jpgNext Steps Toward Commercialisation & Market Applications Jack Perkowski, GMG Chairman and Non-Executive Director, commented: "I am extremely proud that GMG has progressed its battery to this stage. It is a significant milestone for the Company because the battery technology has so much opportunity in so many applications - especially in commercial vehicles. I look forward to the next updates as GMG makes further progress in the development of its battery technology." The Company continues to see a broad range of applications for a completed GMG G+AI Battery - utilising its ultra-high power-density and economic energy density characteristics. Along with Rio Tinto, a range of global companies have confidentially expressed their interest in working with GMG in the following vertical sectors:  Figure 7: Market Applications To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_007full.jpg Currently, GMG believes it will use a plastic battery pack design, similar to Figure 8, to hold the battery pouch cells - reducing the weight, cost and complexity of using a metal case. Using a plastic battery pack is possible for two main reasons - GMG believes that its battery will not require a thermal management system or the fireproofing precautions provided by the metal case in a lithium-ion battery. Using plastic will increase the comparative energy density of GMG's G+AI battery packs when compared to lithium-ion batteries.

Figure 7: Market Applications To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_007full.jpg Currently, GMG believes it will use a plastic battery pack design, similar to Figure 8, to hold the battery pouch cells - reducing the weight, cost and complexity of using a metal case. Using a plastic battery pack is possible for two main reasons - GMG believes that its battery will not require a thermal management system or the fireproofing precautions provided by the metal case in a lithium-ion battery. Using plastic will increase the comparative energy density of GMG's G+AI battery packs when compared to lithium-ion batteries.  Figure 8: Expected Battery Pack for G+AIB Pouch Cells To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_008full.jpgComparison and Market Review: LTO Batteries As shown in Figure 9 below, the performance of GMG's G+AI battery technology is already very similar to LTO batteries. Figure 9: Comparison of Graphene Aluminium-Ion Battery (G+AI) to Lithium Titanate Oxide (LTO) Battery

Figure 8: Expected Battery Pack for G+AIB Pouch Cells To view an enhanced version of this graphic, please visit: https://images.newsfilecorp.com/files/8082/278044_3e8dbe4f44c75b4b_008full.jpgComparison and Market Review: LTO Batteries As shown in Figure 9 below, the performance of GMG's G+AI battery technology is already very similar to LTO batteries. Figure 9: Comparison of Graphene Aluminium-Ion Battery (G+AI) to Lithium Titanate Oxide (LTO) Battery| Parameter | High Power LTO[4] | GMG G+AI Battery |

| Rapid Charging | 80% in 6 minutes | 100% in 6 minutes |

| Energy Density - 6-minute charge | 37 Wh/kg (80% of Capacity) 46 Wh/kg (6 min +) | 26 Wh/kg(Current) Large upside to be confirmed |

| Depth of Discharge | Full Range | Full Range |

| Safety | Safe | Safer (no lithium fire potential) |

| Longevity | 70% performance over 20,000 cycles | To be confirmed |

| Battery Price | US$800 - US$1500 / kWh[5] | Lower price due to lower material costs No lithium, no Titanium |

| Market Size | US$5.6 Billion in Sales in 2025 | Under development |

- Commercial Vehicles: Automotive, primarily buses, refuse trucks, and drayage tractors rather than passenger cars, is the largest user of LTO batteries. Fleets realize five-year total-cost-of-ownership parity once fuel savings and lower maintenance offset higher upfront prices.

- Fast-charging Electric Buses and Trucks: Transit authorities need battery systems that accept repeated high-power "opportunity charges" during short layovers. LTO cells replenish 80% capacity in roughly five minutes, allowing operators to shrink fleet size without sacrificing route frequency. U.S. Low-No Emission Bus grants earmark more than US$1.5 billion per year, with bid specifications that explicitly reference rapid-charge capability. Parallel subsidy programs in China reimburse up to CNY 80,000 (US$ 11,396) per new-energy bus, accelerating volume deployment in provincial capitals.

- Hybrid and BEV: Regenerative braking and high-C-rate acceleration favour the use of LTO batteries. Use in fast-charge EV stations is growing rapidly as ride-hailing fleets adopt swap-ready models.

- Stationary Storage: Utility-scale batteries now cycle multiple times per day for frequency regulation, peak shaving, and voltage support. Energy-storage-system integrators adopt LTO batteries for grid-frequency response where state-of-charge swings are shallow but frequent.

- Industrial Robotics: LTO batteries are used in continuous-duty forklifts that require partial charges during operator breaks.

- Aerospace and Defense: Unmanned aerial vehicles, missile auxiliaries, and soldier-worn power banks operating from -40 °C to +60 °C ambient.

- 5-minute Battery-Swap Stations: Battery-as-a-service platforms require ultra-fast turnaround and high cycle life. CATL confirmed plans to install 1,000 swap stations in 2025 and 30,000-40,000 by 2030, each requiring packs that tolerate thousands of rapid exchanges without degradation.

- Sub-10 kWh Packs: Cordless construction tools, autonomous ground vehicles, and medical carts select LTO batteries to bypass daily pack swaps.

- 12V starter replacement to Lead acid: GMG's G+AI battery technology would be a viable 12 V starter-battery replacement for lead-acid, offering lower weight, longer cycle life, good low-temperature performance and improved cold-cranking capability, together with excellent tolerance to storage at 0% state of charge. In suitable system designs, the chemistry's stable voltage behaviour can also reduce balancing requirements and simplify battery management, helping to lower overall system cost.

- Lifecycle Procurement Preference: Many government procurement frameworks now weigh lifecycle reliability higher than purchase price. For example, New Mexico awarded a US$ 400 million bus electrification contract that included stringent thermal-runaway resistance metrics. Europe's Clean Industrial Deal allocates capital for storage technologies that stabilize renewables, aligning well with LTO batteries' fast-response profile.

- Cylindrical Cells: accounted for 37.7% of LTO battery sales in 2024 as entrenched production lines and robust steel casings satisfied heavy-duty demand. Pouch designs address aerospace weight requirements and constrained dashboards in autonomous robots.

- Produce Graphene and improve/scale cell production processes

- Build Revenue from Energy Savings Products

- Develop Next-Generation Battery

- Develop Supply Chain, Partners & Project Execution Capability

- Craig Nicol, Chief Executive Officer & Managing Director of the Company at craig.nicol@graphenemg.com, +61 415 445 223

- Leo Karabelas at Focus Communications Investor Relations, leo@fcir.ca, +1 647 689 6041

[1]Lithium Titanate Oxide Battery Market Size, Share & 2030 Growth Trends Report[2] LFP: https://www.evlithium.com/catl-battery-cell/catl-150ah-lifepo4-battery-cell.html LNMC: https://keheng-battery.com/product/catl-nmc-3-7v-151ah-high-energy-density-battery-for-ev/ LTO: https://www.global.toshiba/ww/products-solutions/battery/scib/product-next/product/cell/high-power.html Lead Acid: https://www.altronics.com.au/p/s4530-12v-3.5ah-sealed-lead-acid-sla-battery/?srsltid=AfmBOoqZGMEIsX__YYOuRLC3nvYDFtNkf35qZYuYeoh3ACf4wrrOLISD[3]https://findingspress.org/article/21459-impact-of-charging-rates-on-electric-vehicle-batt [4]High-power type cells | SCiB™ Rechargeable battery | Toshiba[5]https://www.ritarpower.com/industry_information/The-Price-of-50-kWh-Lithium-Ion-Batteries-A-Comprehensive-Analysis_297.html#:~:text=Lithium%20Titanate%20(LTO)%20Batteries%3A,cost%20between%20%2440%2C000%20and%20%2460%2C000. [6]https://www.grepow.com/blog/battery-energy-density.html[7]Lithium Titanate Oxide Battery Market Size, Share & 2030 Growth Trends Report

The issuer is solely responsible for the content of this announcement.

Source https://www.media-outreach.com/news/australia/2025/12/15/437796/